Pastmatic Gelato Machine and Pasteurizer

For a perfect mix

The PASTMASTIC unit is a single machine that provides pasteurization, cooling, aging process with only taking up minimal space

Through the PASTMASTIC your gelato base is quickly and easily, ready to be frozen in the Bravo batch freezer Gelmatic M or in the Trittico series.

Gelato and Premium Ice-cream Base Heater, Mixer, Ager and Cooler Machine

Talk with our friendly experts.

Tom Graves Founder, Owner

CALL (949) 212-9753

Get a QuoteTwo model types:

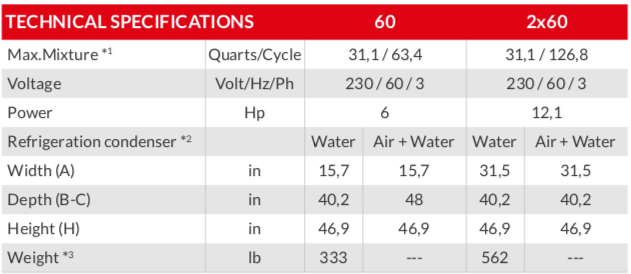

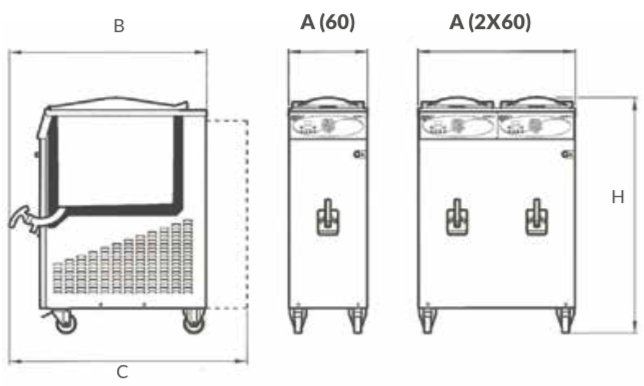

• PASTMATIC 60 can pasteurize up to 63,4 quarts of mixture

• PASTMATIC 2X60 is equipped with 2 independent elliptical tanks for production up to 126,8 quarts gelato base. Each unit automatically runs “high” and “low” temperatures during pasteurization cycles

The Pastmatic combines three operations in only one appliance: heating, aging and cooling in accordance with the HACCP regulations. The special central stirrer presses the mixture in order to have a more uniform mix of the ingredients and to boost the thermal exchange between the mixture and the wall of the tank. A digital electronic board completely controls the machine and, through very precise sensors, controls the heating, the cooking and the cooling processes of the mixture; this grants that the mixture never burns or becomes frozen even during the preservation cycle.

Technical Features |

|

|

|

Advantages and Strengths |

|

|

|

PATENTED ELLIPITCAL TANKS OF THE NEW GENERATION

The Elliptical tank offers the advantage to make the mixture run smoothly along it’s walls without beating during the stirring process to prevent lumps. This is the perfect thermal exchange, if compared to other shapes.

NEW TANK HEATING SYSTEM

This system is essentially designed for a careful heating management, which keeps the organoleptic properties without altering the quality and taste of the food. The heating system radiates heat and makes mixture absorb it in a smooth and nonaggressive way. Armored heating elements ensure no thermal inertia – which only occurs in bain-marie heating system to avoid the most delicate ingredients to burn. In addition, the new system is Duo: for heating and cooling.

SMART TANK COOLING SYSTEM

Tank is equipped with a smart and quick cooling system on both its bottom – side which keeps longer in contact with the mixture – and it’s side walls to avoid the “igloo” effect. “Igloo” effect occurs when moisture comes from the external environment gathers on the walls of the tank, turns into ice and then melts affecting the quality of the mixture. Pastmatic ensures a gentle and high-quality cooling of the mixture even for low quantity of product. The new evaporator for the cooling process grants the same performance and is equipped to perform with half of the power installed.

NEW STIRRER-PUMP WITH HIGH MIXING PERFORMANCES

The New Stirrer is covered by a patent: the device has now increased by 20% mixing and aspiration performances. The stirrer pump operates through sucking in the mixture and intensely rubbing the bottom of the tank to break down the content into liquids. Results by the effective heat exchange to getting a smooth and homogeneous base. Stirrer can be removed from the top to prevent unhygienic and difficult-to-clean deposits on the bottom of the tank.

QUICK AND RELIABLE CLEANING PROCESS

Hygiene is essential in food processing and requires critical issue, time and resources. Pastmatic is designed to make this process be as easy and smooth as possible. This process allows: QUICK cleaning: user can clean, disassemble, and re-assemble the few components during the pasteurizing process in efficient time. EASY cleaning: all the components to be cleaned are visible and immediately identifiable, easy to reach parts. DEFINITE cleaning: once the few involved components are cleaned, the user is certain that the machine is sanitized for the next production cycle.

NEW ELECTRONIC BOARD “DUO SERIES”

A powerful machine is nothing without control. Thanks to the new digital electronic board and to the new generation probes, Pastmatic automatically and accurately controls mixing speed, temperatures and heating times. Cooking and cooling process ensures the mixture not to burn or to freeze during the preservation process. Everything is always under control and easy to use, thanks to the Pre-Set and free production programs

Technical Specifications

Bravo Trittico – Start of the revolution: in 1974 Genesio, founder of Bravo, submitted the first of a long series of patents: Trittico, the first and only complete laboratory enclosed in just one machine, which is less than three square feet can pasteurize and batch freeze high-quality artisan gelato. A patent that radically changes the way of thinking of the artisan gelato workshop. With Trittico a new way of making gelato has begun: the Trittico method, the new Bravo adventure, one machine that’s the most copied machine in the world today.

Bravo Brochures and Specification Sheets

Bravo Trittico Mechanic

Bravo Trittico Business

Bravo Trittico Executive

Bravo Gelmatic M

Bravo Pastmatic

Bravo Trittico EVO

Bravo G-20

Refrigeration & Other

Related Products

Bravo Trittico M 30 Mechanic

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More

Bravo Trittico M 120 Mechanic

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More

Bravo Trittico M 50 Mechanic

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More