Bravo G-20 Batch Freezer

Easy and Fast – Bravo G-20 Table Top Horizontal Batch freezer

The Bravo G-20 tabletop horizontal batch-freezer for gelato & ice cream production is small and productive. Easy to use, strong and reliable, Gelmatic Mechanic makes artisan’s work easy and safe, as it reaches a very low temperature in a very short time.

Batch-freezer for gelato & ice cream production with cold process

Talk with our friendly experts.

Tom Graves Founder, Owner

CALL (949) 212-9753

Get a Quote Gelmatic Mechanic series are extremely reliable machines, designed to be easy to use (few push buttons with basic functions) and are an advanced batch freezer for restaurants and coffee shops, used for the production of high-quality gelato and ice cream. The G-20 can fit anywhere and is easy to transport thanks to its compact size. High-performance batch-freezer that allows obtaining results above market standards, thanks to the high freezing system technology, that takes advantage of most of the heat exchange for an optimal cooling and resulting freezing of gelato mixture. Easy to load through the upper funnel that allows to easily pour the product from the buckets, avoiding the air outflow from the cylinder door.

Gelmatic Mechanic series are extremely reliable machines, designed to be easy to use (few push buttons with basic functions) and are an advanced batch freezer for restaurants and coffee shops, used for the production of high-quality gelato and ice cream. The G-20 can fit anywhere and is easy to transport thanks to its compact size. High-performance batch-freezer that allows obtaining results above market standards, thanks to the high freezing system technology, that takes advantage of most of the heat exchange for an optimal cooling and resulting freezing of gelato mixture. Easy to load through the upper funnel that allows to easily pour the product from the buckets, avoiding the air outflow from the cylinder door.

Technical Features |

|

|

|

Advantages and Strengths |

|

|

|

“I love my Bravo ice cream machine. Really! It’s easy to clean, freezes really well and fast- and most importantly, it makes great gelato, sorbet and ice cream!” ELIZABETH FALKNER, Chef/Pastry Chef/Author

“I love my Bravo ice cream machine. Really! It’s easy to clean, freezes really well and fast- and most importantly, it makes great gelato, sorbet and ice cream!” ELIZABETH FALKNER, Chef/Pastry Chef/Author| Standup Floor Models Gelmatic 30, 60, 120 30 Available in air or water-cooled 60 and 120 Water-Cooled | Counter-top Model Bravo G-20 Air-cooled and single phase |

|

|

|

|

|

|

| Rounded anti-drip upper edge with “sensible touch” display | Disassemble door for fast cleaning | interchangeable metal scraper | Probe in direct contact with the mix |

Technical Specification |

Model | |

|---|---|---|

| 120 | ||

| Prod. for cycle | .45 | |

| Average hourly production *1 | 5 | |

| Voltage | 230/60/1 | |

| Power | 3.6 | |

| Refrigeration condenser *2 | Air | |

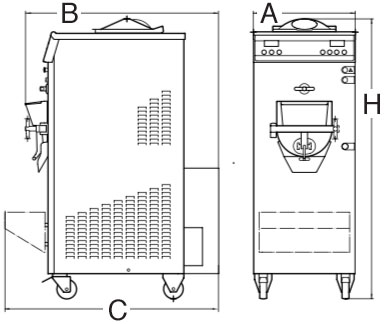

| Width (A) |  In inches In inches |

24 |

| Depth (B) | 45.3 | |

| Depth (C) | 48.2 | |

| Height (H) | 55.1 | |

| Weight *3 | 187 | |

*1 Hourly production may change accordingly to type of mixture and finished product density. *2 Water: cooled system self contained. Air+Water: cooled system self contained. *3 The weight of the air cooled machines will be estimated before the shipment.

Bravo Trittico – Start of the revolution: in 1974 Genesio, founder of Bravo, submitted the first of a long series of patents: Trittico, the first and only complete laboratory enclosed in just one machine, which is less than three square feet can pasteurize and batch freeze high-quality artisan gelato. A patent that radically changes the way of thinking of the artisan gelato workshop. With Trittico a new way of making gelato has begun: the Trittico method, the new Bravo adventure, one machine that’s the most copied machine in the world today.

Bravo Brochures and Specification Sheets

Bravo Trittico Mechanic

Bravo Trittico Business

Bravo Trittico Executive

Bravo Gelmatic M

Bravo Pastmatic

Bravo Trittico EVO

Bravo G-20

Refrigeration & Other

Related Products

Bravo Trittico M 50 Mechanic

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More

Bravo Batch Freezer – Gelmatic M

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More

Bravo G200 High Overrun Batch Freezer

Heat & Freeze Machines for making Gelato, Ice Creams & Sorbets

Read More